In Stock

In Stock Fast Dispatch

Fast Dispatch

Min Order:

Once e-Contract is confirmed Buyer and supplier, Comb2b.com will:

1 ) offer Buyer a designated Bank Account for making payment,Once e-Contract is confirmed Buyer and supplier, Comb2b.com will:

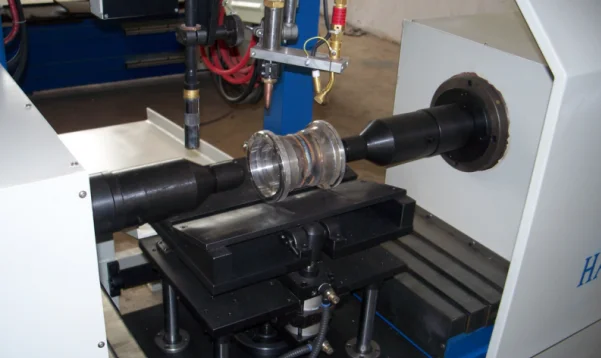

1 ) Recommend the below Digital Currency Exchange for buyers to convert local currency to USDT / USDC.Excavator Track Roller Idler Automatic Welding Machine

Design task

The roller ring line welding machine should be able to complete the multi-layer welding of U-shape line and V-shape line for various rollers automatically. The work-piece does not need spot welding for position,

it can automatically make pre-heat and stable, continuous welding, the welding line looks good, and size on average, welding section and penetration can reach specification.

1. Fixing welding torch, rotating work-piece and make welding position in horizon.

2. Fixing and rotating work-piece at the same time to assure preventing the welding line in offset.

3. The machine has function to get high voltage and slow supply of welding wire to assure the welding arc reliable and low voltage, small current to end the welding arc to make the arc hole full.

4. Pneumatic loading and unloading is adopted. Welding process is accomplished automatically, so the labor intensity of workers is reduced.

5. To assure wire feed stable, the machine uses pull way to make wire feed.

6. To produce multi-items, the welding torch, spindle box and pneumatic tailstock can be adjusted longitudinally.

7. To position it by hole center and fix it by pneumatic way.

8. To improve machine stability, the work-piece rotation speed is controlled by alternating frequency controller instead of level adjusting, and the machine controller is PLC.

9. Welding type, welding specification can be set-up, reserved and selected as working. It is convenient to change parameter and the situation by touch screen.

10. To reach welding requirement, the welding torch can be travelled up and down, left and right and also can be positioned in different angle.

11. It can setup automatic pre-heat, pre-heat time and length.

12. One operator, it can make pre-heat and welding separately.

Working process

Loading by worker→elevating work-piece→fixing work-piece by pneumatic way→elevating table goes down→close the door→positioning pre-heat torch→

automatic pre-heat→pre-heat torch goes back→welding torch goes down→Positioning→supply co2 gas→high voltage,get arc by supplying welding wire→

after checking the welding current→rotating work-piece, and start welding→reach the setting welding length→elevating the welding torch, and Amplitude →

reach the setting welding length→small current and low voltage to end the arc→stopping co2 supply→elevating table goes up→release the work-piece→

elevating table goes down → open the door→ take work-piece outside

Spindle Speed | 1-8r.p.m, stepless speed |

Motor power | 0.75KW |

Compressed air | 0.4-0.6MPa |

Welding wire diameter | 0.8-1.6mm |

Elevating travel | 100mm |

X-axis travelling | 100mm |

Angle | 25°~ 60° |

Welding current | 50-500A,60% of it for loading. |

Welding voltage | 15-36V, stepless speed |

Capacity | 1 piece/2 minutes |

Excavator Track Roller Welding machine

Check

Check

Click this button, freight and tax will be updated